Towards the development of the First Regenerative sOlid-STate Barocaloric refrIgeraTor

Project

In 2019, refrigeration systems worldwide emitted as much greenhouse gases as the amount emitted in the entire European Union. This impact is largely due to the frequent leaks of refrigerant fluids, which represent 30% per year of the fluids consumed by the cold storage rooms of a supermarket. Among the most polluting gases lost to the atmosphere are hydrofluorocarbons (HFCs), whose global warming potential is up to thousands of times higher than CO2. Given this situation, experts agree that even the slightest improvement in refrigeration systems will benefit the carbon footprint of our planet.

The FROSTBIT project has been launched to drive progress towards more sustainable cooling technologies based on pressurized solids. FROSTBIT aims to develop an all-solid system based on spin transition materials.

“We are doing barocaloric refrigeration. This involves applying pressure variations to a spin-crossover material to generate heat exchanges between the material and the environment, thus creating cold,” explains Patrick Rosa, CNRS researcher at the Institute of Chemistry of Condensed Matter of Bordeaux and Scientific Coordinator of the project.

“We are doing barocaloric refrigeration. This involves applying pressure variations to a spin-crossover material to generate heat exchanges between the material and the environment, thus creating cold,” explains Patrick Rosa, CNRS researcher at the Institute of Chemistry of Condensed Matter of Bordeaux and Scientific Coordinator of the project.

The consortium brings together various European research groups, combining expertise ranging from the synthesis of materials using green chemistry processes, to the characterization of the barocaloric properties of the resulting materials and device engineering. FROSTBIT includes nine public and private partners from four European countries: CNRS, which coordinates the project, its subsidiary CNRS Innovation, the University of Bordeaux, the University of Lorraine, the University of Tours, TOTAL Energies OneTech in France, the Universitat Politècnica de Catalunya in Spain, the University of Ljubljana in Slovenia, and the University of Kent in the UK.

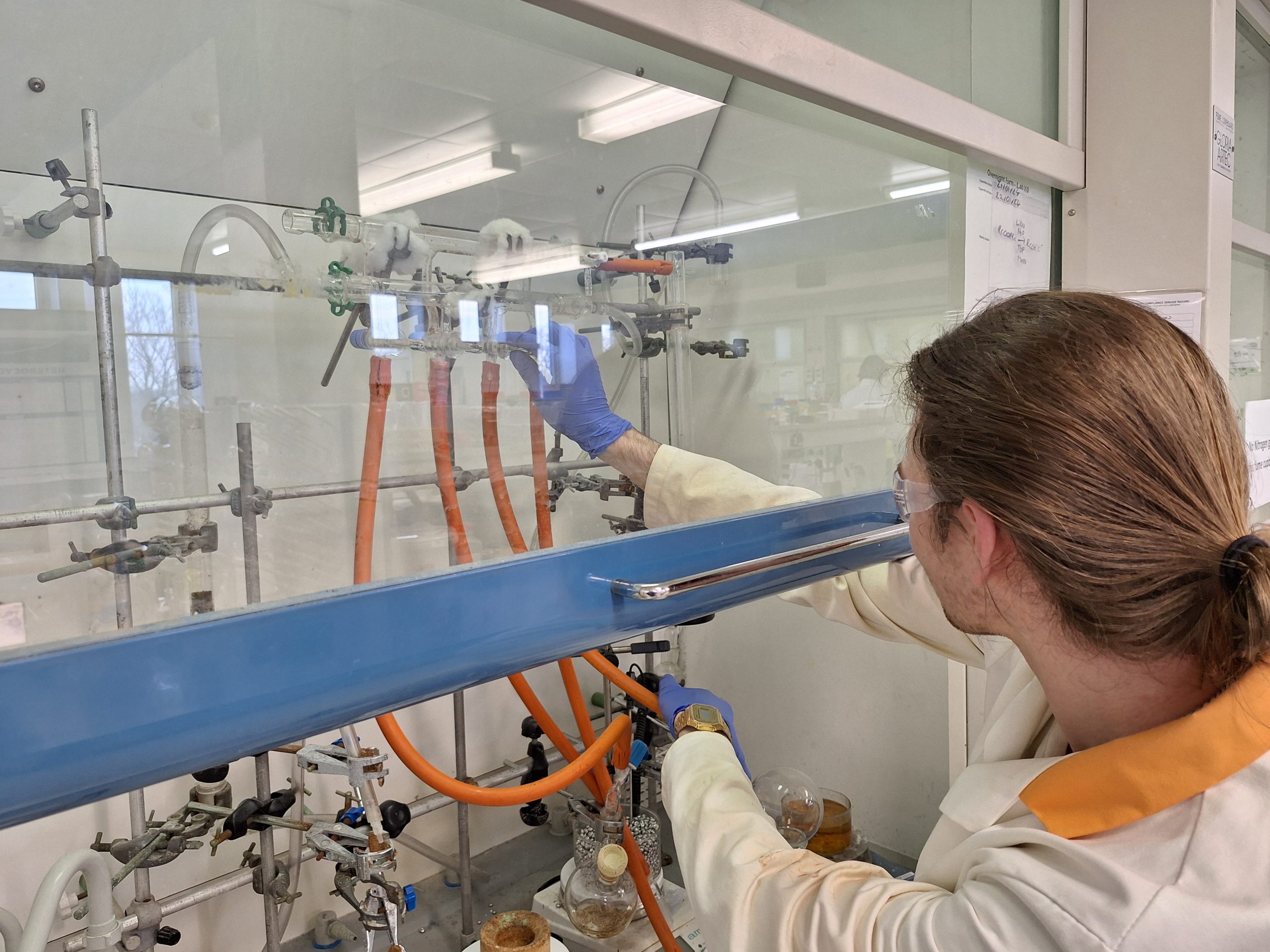

First steps will involve developing new molecular compounds with sustainable and low-cost synthesis, both economically and environmentally—a challenge being addressed by Prof. Helena Shepherd’s group at the University of Kent.

“The FROSTBIT project is especially meaningful to us because it represents a real opportunity to apply sustainable chemistry to a pressing global challenge—solid-state cooling. We’re excited about its potential to develop eco-friendly alternatives to traditional cooling systems, which often rely on harmful refrigerants. The idea of creating more efficient, greener thermal management solutions isn’t just scientifically interesting—it’s a chance to make a tangible, positive impact on both industry and the environment”, Helena says.

“The FROSTBIT project is especially meaningful to us because it represents a real opportunity to apply sustainable chemistry to a pressing global challenge—solid-state cooling. We’re excited about its potential to develop eco-friendly alternatives to traditional cooling systems, which often rely on harmful refrigerants. The idea of creating more efficient, greener thermal management solutions isn’t just scientifically interesting—it’s a chance to make a tangible, positive impact on both industry and the environment”, Helena says.

At the Bordeaux Institute of Condensed Matter Chemistry (ICMCB), Patrick Rosa’s group will shape optimal candidates through sintering, a process that transforms powder into centimeter-sized ceramics to increase density and improve heat transfer.

“For us, FROSTBIT is a great opportunity to apply the combined expertise we have cultivated during the last twenty years on spin-crossover materials and sintering techniques, to compact powder into densified centimetre-sized ceramics that maximize material performance and help developing efficient barocaloric devices”, Patrick Rosa says.

“For us, FROSTBIT is a great opportunity to apply the combined expertise we have cultivated during the last twenty years on spin-crossover materials and sintering techniques, to compact powder into densified centimetre-sized ceramics that maximize material performance and help developing efficient barocaloric devices”, Patrick Rosa says.

A comprehensive study of the materials will also include structural characterization under pressure using diffraction techniques at the University of Lorraine.

Prof. Dominik Schaniel, Principal Investigator at the University of Lorraine, says: “Building on our vast experience in creating methods and tools for structural analysis of advanced functional materials, we are now focusing this expertise on barocaloric Spin Crossover materials.”

Prof. Dominik Schaniel, Principal Investigator at the University of Lorraine, says: “Building on our vast experience in creating methods and tools for structural analysis of advanced functional materials, we are now focusing this expertise on barocaloric Spin Crossover materials.”

The Group of Characterization of Materials at the Center for Research in Multiscale Science and Engineering (CCEM) and part of the Department of Physics at Universitat Politècnica de Catalunya, will perform the characterization of the thermal response of the materials to pressure changes, both in powder and ceramic form. The results will be used for materials filtering.

“FROSTBIT represents the opportunity of contributing closely to bring to real technology our knowledge on the material side. It appears as the natural evolution of basic research, as our responsibility to give back to society” says Josep Lluís Tamarit, Principal Investigator and Head of the Group of Characterization of Materials at the Universitat Politècnica de Catalunya.

“FROSTBIT represents the opportunity of contributing closely to bring to real technology our knowledge on the material side. It appears as the natural evolution of basic research, as our responsibility to give back to society” says Josep Lluís Tamarit, Principal Investigator and Head of the Group of Characterization of Materials at the Universitat Politècnica de Catalunya.

To build an efficient barocaloric refrigerator, all the materials properties must be exploited at their full potential. It is essential to find suitable shapes, compositions, and composites to reach the highest possible thermal conductivities and exchange a large amount of heat. This requires measuring thermal conductivity on very different structures: powders, uniform ceramics, composites, and understanding how it varies at a fundamental level. This task will be carried out at GREMAN Laboratory, at the University of Tours.

“Participating in the project FROSTBIT is a real opportunity to reveal the importance of thermal conductivity for barocaloric materials, an overlooked topic, and to enrich its portfolio of activities on materials for energy”, says Prof. Fabien Giovanelly, Principal Investigator at University of Tours.

“Participating in the project FROSTBIT is a real opportunity to reveal the importance of thermal conductivity for barocaloric materials, an overlooked topic, and to enrich its portfolio of activities on materials for energy”, says Prof. Fabien Giovanelly, Principal Investigator at University of Tours.

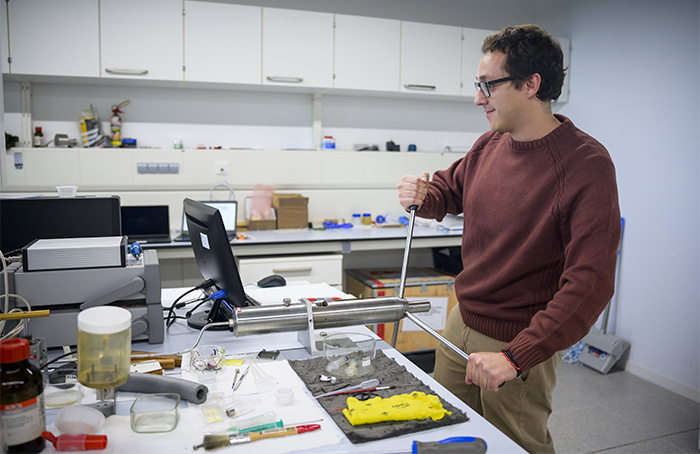

The Laboratory for Non-Linear Mechanics at the University of Ljubljana, with long expertise in elastocaloric devices and also magnetocaloric methods, will address the modelling, design and construction of the barocaloric device. Several iterative exchanges with thermal engineers will then help optimize the design of heat exchangers. They will determine the forms of ceramics to produce, their technical feasibility, and the other components of a small refrigeration system, including regenerator, thermal and pressure fluid circuits. The goal in the long term is to develop a prototype (TRL 4) that will deliver 100 watts of refrigeration power at room temperatures and provide a temperature span of at least 20 K with a target COP between 4 and 6 (corresponding to 30% of Carnot efficiency).

Prof. Jaka Tušek, Principal Investigator at this Institution, says:

“The FROSTBIT project stands out as one of the most exciting endeavors we’ve tackled so far. We’re truly enjoying its interdisciplinary nature, which encompasses every stage of development – from material processing and characterization to its implementation in an innovative cooling device. Leveraging our extensive experience in designing elastocaloric devices, we are applying this expertise to a new yet analogous barocaloric technology. We’re eager to tackle the current challenges in barocalorics and aim to significantly accelerate the advancement of this promising technology to new heights.”

Prof. Jaka Tušek, Principal Investigator at this Institution, says:

“The FROSTBIT project stands out as one of the most exciting endeavors we’ve tackled so far. We’re truly enjoying its interdisciplinary nature, which encompasses every stage of development – from material processing and characterization to its implementation in an innovative cooling device. Leveraging our extensive experience in designing elastocaloric devices, we are applying this expertise to a new yet analogous barocaloric technology. We’re eager to tackle the current challenges in barocalorics and aim to significantly accelerate the advancement of this promising technology to new heights.”